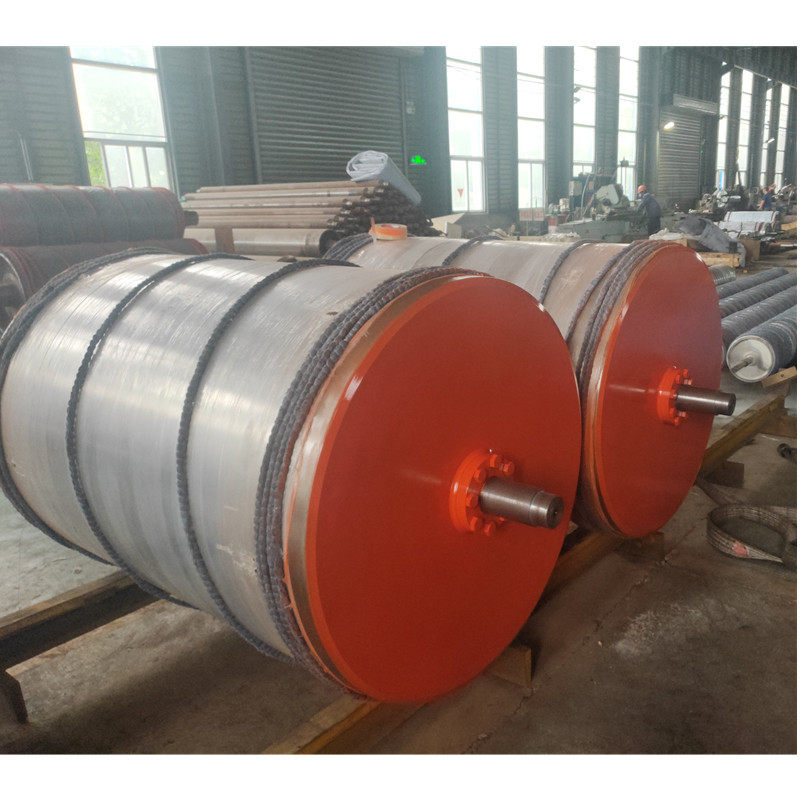

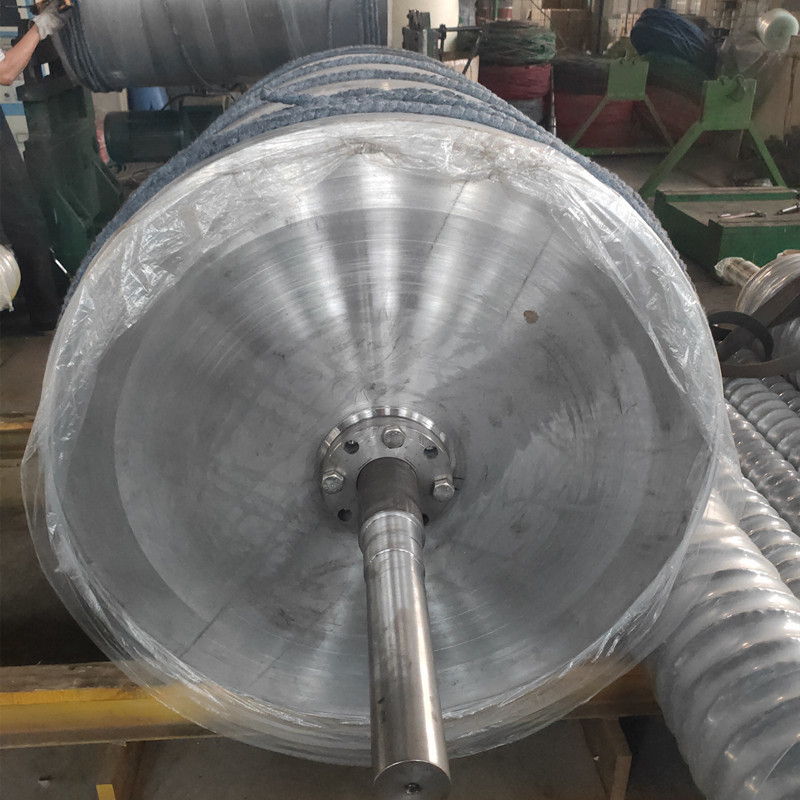

Stainless steel shaft roller /304 roller

The stainless steel roller conveyor has a large conveying capacity; the traction chain has high strength and can be used for long-distance conveying; and the layout of the transmission line is flexible. Compared with the mesh belt conveyor, the stainless steel roller conveyor can convey under a larger skew angle and a smaller bending radius, so the flexibility of placement is greater. The angle of the stainless steel roller conveyor can reach 30°-35°, and the bending radius is generally about 5-8m; various processings such as sorting, drying, cooling or assembling can be carried out during the conveying process.

The operation is stable and reliable; the structure of the stainless steel roller conveyor is varied. Stainless steel roller conveyors are generally classified as follows: according to the device form of the roller conveyor, it can be divided into fixed and mobile; according to the layout of the roller conveyor, it can be divided into horizontal, horizontal, skewed, horizontal skewed, etc.

The material conveyed by the roller conveyor is in a closed state from the inlet to the outlet, and the outlet does not need to be equipped with a dust collector, which can ensure that no dust leaks into the environment during the conveying of the material. The material is smoothly conveyed along the roller conveyor, and there is no internal movement at all, so the conveyed material is less damaged, and the slow roller conveying causes very little damage to the conveyed material.

Video

The stainless steel roller conveyor has a large conveying capacity; the traction chain has high strength and can be used for long-distance conveying; and the layout of the transmission line is flexible. Compared with the mesh belt conveyor, the stainless steel roller conveyor can convey under a larger skew angle and a smaller bending radius, so the flexibility of placement is greater. The angle of the stainless steel roller conveyor can reach 30°-35°, and the bending radius is generally about 5-8m; various processings such as sorting, drying, cooling or assembling can be carried out during the conveying process.

Tag:

Pre